1. Summary

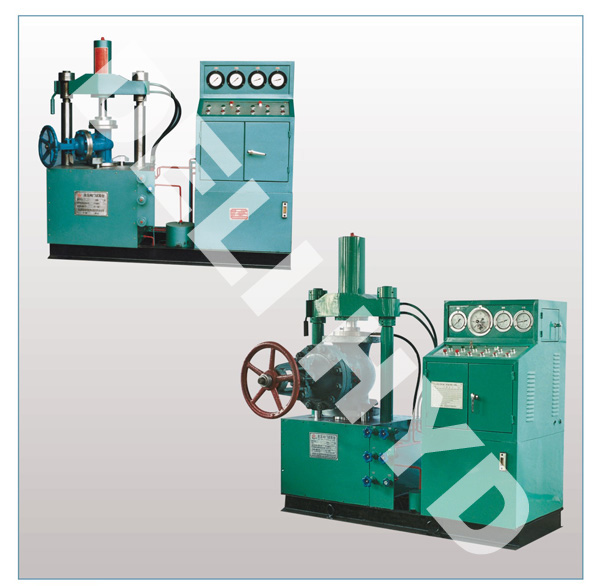

The hydraulic valve test bench of model YFS-L is used to perform shell test and seat test of flanged valves,such as gate valves,ball valves,globe valves,check valves etc., welded valves with small size,socket welded valves, screwed valves,etc.,adopting the way of jaw clamping and cylinder goring.Test benches of this model are wild in use,easy in operation,and high in efficiency.

2. Technical Parameters

Model&

Specification |

TestingRange |

Diameter & Quantity of Clamping Oil Cylinder |

Diameter &Quantiyt of Goring Oil Cylinder |

Max.Clamping Force (t) |

Motor of Oil Pump |

Outline Dimensions(L×W×H) |

| YFS-L100 |

DN15-100 |

φ80×3 |

φ120×1 |

30 |

2.2KW |

700×1710×1680 |

| YFS-L200 |

DN50-200 |

φ100×3 |

φ150×1 |

50 |

2.2KW |

700×1800×1780 |

3. Pressure Check List

Model YFS-L100

| Nominal Diameter |

Nominal Pressure MPa/class |

|

1.6 |

2.5 |

4.0 |

6.4 |

10.0 |

16.0 |

20.0 |

25.0 |

32.0 |

|

|

150 |

300 |

400 |

600 |

900 |

|

1500 |

|

|

Pressure of Hydraulic Station |

| in |

mm |

PN |

PS |

PN |

PS |

PN |

PS |

PN |

PS |

PN |

PS |

PN |

PS |

PN |

PS |

PN |

PS |

PN |

PS |

| 1/2″ |

DN15 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

| 3/4″ |

DN20 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

| 1″ |

DN25 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

| 11/4″ |

DN32 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

| 11/2″ |

DN40 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

| 2″ |

DN50 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

| 21/2″ |

DN65 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|

|

| 3″ |

DN80 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|

|

|

|

| 4″ |

DN100 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|

|

|

|

|

|

|

|

Model YFS-L200

| Nominal Diameter |

Nominal Pressure MPa/class |

| 1.6 |

2.5 |

4.0 |

6.4 |

10.0 |

16.0 |

20.0 |

25.0 |

32.0 |

|

150 |

300 |

400 |

600 |

900 |

|

1500 |

|

|

Pressure of Hydraulic Station |

| in |

mm |

PN |

PS |

PN |

PS |

PN |

PS |

PN |

PS |

PN |

PS |

PN |

PS |

PN |

PS |

PN |

PS |

PN |

PS |

| 2″ |

DN50 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

| 21/2″ |

DN65 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

| 3″ |

DN80 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

| 4″ |

DN100 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|

|

| 5″ |

DN125 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|

|

|

|

|

|

| 6″ |

DN150 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|

|

|

|

|

|

|

|

| 8″ |

DN200 |

● |

● |

● |

● |

● |

● |

● |

● |

|

|

|

|

|

|

|

|

|

|

PN-denotes the pressure of the oil cylinder when performing seat test;PS- denotes the pressure of the oil cylinder when performing shell test

|